MIG welding feeds a wire consumable electrode continually to the weld. This makes it quicker, which is great for louder and thicker materials. It is user friendly and widely used in manufacturing, car repair etc. But it can get messier and is not as precise.

TIG has the non consumable tungsten electrode and separate filler rod. This provides better control and accuracy resulting in clean, honest welds on any project, no matter the material-even aluminium & stainless steel. It’s a slower, more difficult and worse process for the welder to learn anyway.

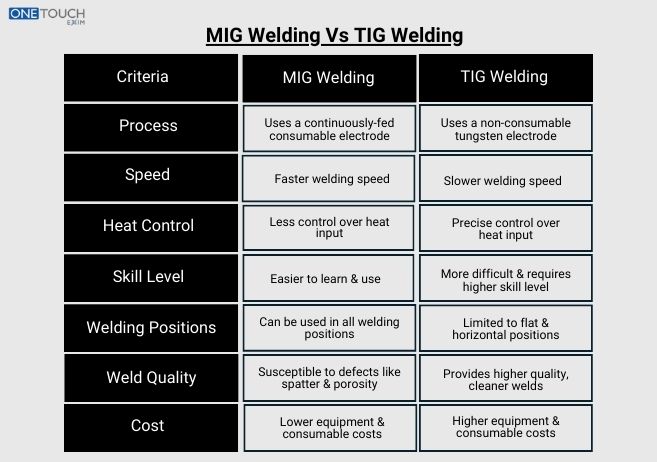

Comparison Between MIG Welding Vs TIG Welding:

MIG Welding MIG welders use a wire welding electrode on a spool that is fed automatically at a constant pre-selected speed. MIG is the easiest type of welding to learn and is great for light fabrication, maintenance repair work or automotive work. You see it a lot in auto work, and for fabrication or do it yourself. However, it does not offer as much control and may splatter.

TIG welding utilizes a non-consumable tungsten electrode and filler metal, typically used by hand. This provides the freedom to control and adjust materials such as aluminium and stainless steel. It is a slower, more involved technique and requires a high degree of operator expertise.

In other words, grab MIG for speed and ease on steel, while grabbing TIG for improved quality and control with more options for a variety of materials.

| Criteria | MIG Welding | TIG Welding |

| Process | Uses a continuously-fed consumable electrode | Uses a non-consumable tungsten electrode |

| Speed | Faster welding speed | Slower welding speed |

| Heat control | Less control over heat input | Precise control over heat input |

| Skill level | Easier to learn and use | More difficult and requires higher skill level |

| Welding Positions | Can be used in all welding positions | Limited to flat and horizontal positions |

| Weld Quality | Susceptible to defects like spatter and porosity | Provides higher quality, cleaner welds |

| Cost | Lower equipment and consumable costs | Higher equipment and consumable costs |

What is Metal Inert Gas (MIG) Welding Process?

MIG (Metal Inert Gas) welding, also known as GMAW, is a welding process in which wire is used as the electrode metal and it can be fed through a welding gun. An inert or semi-inert gas flows from the welding gun to protect the electrode from contaminants in the air, oxygen.

A wire melts as an electric arc is directed between it and the workpiece, fusing the two together. The constant fast feed feed – it is the wire that gives here, away with which flows it again, this makes MIG a fast-working and effective process. Due to its speed and ease of learning, SAW is the most commonly used autogenous welding method.

What is the Tungsten Inert Gas (TIG) Process?

Tungsten Inert Gas welding is a precise arc welding process using a non-consumable tungsten electrode to make the weld. An arc is formed between this electrode and the workpiece, and it’s used to produce a high level of heat. Additionally an independent filler rod is manually brought to the weldpool optionally.

The whole process is protected from the atmosphere by a shield of inert gas flowing through the torch, which shields the molten weld pool and tungsten electrode. This technique allows for a degree of control that is not super cased, thus enabling the operator to make sharp high quality welds without spattering. It is technically straight forward, but it takes quite a bit of skill and coordination. TIG is a perfect welding process for welding thin materials, crucial joints or non-ferrous metals such as aluminium, stainless steel and copper alloys.

Types of Materials

TIG Welding and MIG Welding : TIG vs MIG is based on the materials you plan to weld.

MIG is versatile and works best when you are welding mild steel or stainless steel to a thicker gauge. Its fast performance makes it perfect for use on carbon steels in light industrial and automotive applications. It can accommodate aluminium with a spool gun, but it may not be as neat and clean as TIG.

This TIG Welder provides more accurate control of the welding arc and reliable quality welds in all types of material, including aluminum, stainless steel and chrome moly. It is the recommended option for fusing thin gauges of stainless, aluminium and magnesium because you have much more control over heat. TIG is also a must for reactive metals such as titanium and copper based alloys, which require purity of the weld in order to avoid contamination and embrittlement.

In other words, MIG is “tough” (for popular steels) and TIG gives the fine control that thinner, exotic or thin materials require.

Applications

The uses of MIG and TIG welding are different based on their specialities in speed vs accuracy.

MIG Welding is the process of choice for high volume production and fabrication. Applications include automotive assembly and repair, shipbuilding, construction industry operations, and general plant equipment/machinery such as machine tools. Best used for long, continuous welds on thicker materials to increase productivity.

Conversely, in other words TIG Welding is best suited for the applications that require a certain level of quality, seals and the artistic appearance. It is necessary for aerospace pieces, custom motorcycle and bicycle frames, tubes for sanitary systems (foods, chemical, nuclear), artistic metal work and repairing thin gauged tools. TIG shines most with thin materials and special alloys such as aluminium, stainless steel or titanium, when perfect clean welds are critical.

Conclusion

The decision between MIG and TIG depends on what’s needed for the job at hand. MIG provides the highest quality and most efficient type of welding for steel, fabrication and thicker material. When it comes to thin or exotic metals such as aluminium, nothing beats TIG, choose MIG for speed, TIG for clean (and higher integrity) welds.