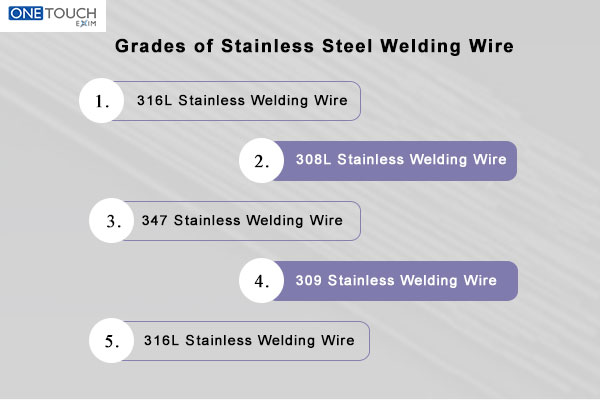

In welding, choosing the right welding rod or wire is critical to achieving strong and durable welds, especially when working with stainless steel. The ss welding rod types , including E308 or ER308, are some of the most commonly used rods for welding stainless steel due to their excellent corrosion resistance and good weldability. However, when it comes to specialized applications, there are various other welding rod types and wires designed for specific needs. This includes options for welding different grades of stainless steel, such as duplex, ferritic, or austenitic stainless steels. Additionally, when hardfacing is required, hardfacing welding rod types are used to improve the wear and resistance of the welded area.

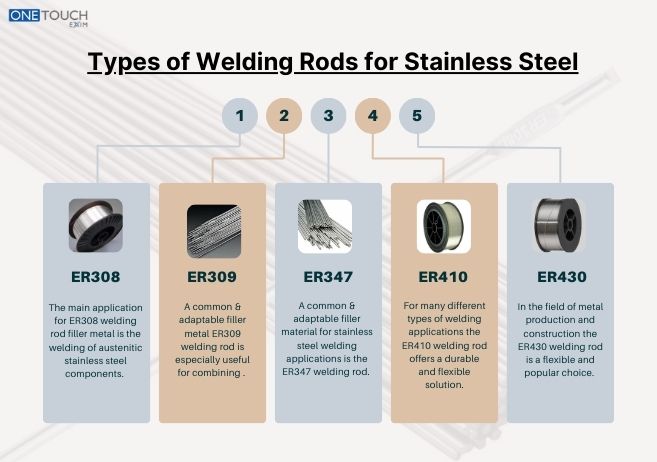

Types of Welding Rods for Stainless Steel

Here we have pointed out various types of welding rods:

1. ER308

The main application for ER308 welding rod filler metal is the welding of austenitic stainless steel components. Because of its ability to create welds with exceptional mechanical qualities and a high degree of corrosion resistance this adaptable electrode is a preferred option for a variety of industrial applications. In order to preserve the austenitic microstructure of the weld metal and stop the formation of harmful phases like ferrite or martensite the ER308 composition contains a precisely balanced combination of nickel and chromium. As a result even under challenging circumstances or with elevated stress the welds are resistant to corrosion, pitting and cracking.

2. ER309

A common and adaptable filler metal ER309 welding rod is especially useful for combining incompatible metals like carbon and stainless steel. Because it is made of an alloy that has been properly balanced the ER309 rod is a popular option for many industrial and fabrication applications because it offers high-strength welds and excellent corrosion resistance. The ER-309 rod helps close the gap between the various base metal compositions and thermal expansion coefficients by depositing a weld bead with a characteristic austenitic stainless steel microstructure when heated and melted in the welding arc. Even in harsh conditions the ER309 can create welds that are resistant to corrosion, cracking and other types of damage due to its unique metallic structure.

3. ER347

A common and adaptable filler material for stainless steel welding applications is the ER347 welding rod. This rod exceptional corrosion resistance and high temperature strength qualities make it perfect for welding stainless steel components. It is made of a particular alloy that contains chromium, nickel and other essential elements. The ER347 rod is made to create consistent smooth weld beads with little to no spatter resulting in joins that are both technically beautiful and long lasting. The unique quality of this welding rod is its resistance to stimulation a condition in which the metal chromium content might decrease in the vicinity of the weld thereby impairing the resistance to corrosion. This problem is avoided in part by the special chemistry of ER347 which guarantees that the welded stainless steel keeps its vital protective qualities even under extremely hot conditions.

4. ER410

For many different types of welding applications the ER410 welding rod offers a durable and flexible solution. This rod which is made of an alloy of stainless steel is well liked for applications requiring high performance welding because of its remarkable strength, resistance to corrosion, and high heat tolerance. Superior hardness and abrasion resistance are imparted to the weld by the ER410 distinctive chemical formula which incorporates chromium as a critical alloying element. For components like mining machinery, industrial fabrications and agricultural equipment that are going to be subjected to a lot of wear and tear this makes it the perfect option for welding.

Besides ER410, a lot of welding electrode types serve specific demands for application and material requirements. These rods ensure the best weld characteristics in high tensile strength, corrosion resistance, and those special features-heat resistance and wear resistance-of critical importance in so many challenging industrial environments.

5. ER430

In the field of metal production and construction the ER430 welding rod is a flexible and popular choice. Because of its outstanding resistance to corrosion this filler material made of stainless steel is highly valued and is a great option for applications where the finished weld will be exposed to corrosive conditions. The rod chemical formula which includes less than 1% carbon and 16 to 18% chromium gives it superior oxidation resistance over more basic stainless steel alloys hence the ER430 his nickname. The ER430 rod composition guarantees the long term integrity of the linked materials by enabling it to create strong ductile welds that are extremely resistant to pitting, crevice corrosion and other types of degradation.

Conclusion

Another vital last step in the processes of welding involves the use of a stainless steel welding rod. Since it has odd features of strength, anti-corrosion, and only with particular methods of welding on stainless steel, one will be able to get a strong, high-quality bond. In sum, the stainless steel welding rod plays an important role because it provides heat control and filler material necessary to create solid, durable welds on stainless steel surfaces.