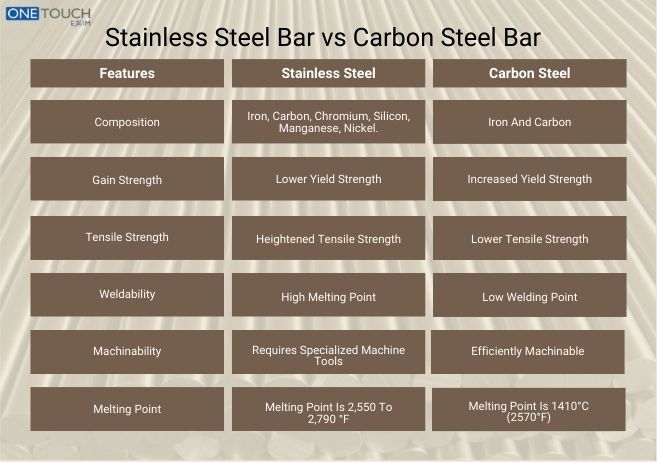

The stainless steel and carbon steel bars are both of the most popular choices in the construction industry. They have two different qualities, properties, and benefits with different uses, making them suitable for application to various industries. In this article, you can explore the key difference between the most commonly used metal stainless steel bars and carbon steel bars.

Stainless Steel Bar

Stainless Steel Bar, known as rod, round bar, stainless steel square bars, and cylinder shapes, make up a wide range of grades like 304, 316, 321, and other common grades. These properties make it popular to apply in the construction and industrial sectors. It is a versatile metal product that offers special properties. It is an excellent choice in mechanical industries, with standing corrosion resistance properties and making it an ideal choice for indoor and outdoor applications.

Basic Composition in Stainless Steel Bar

The stainless steel bar is a composition of iron, chromium, and carbon, with holding contains nickel, copper, and molybdenum, depending on their grades, and their elements combination can enhance ductility, corrosion resistance, durability, staining, and longevity. It’s a combination of iron and other elements, which is called stainless steel, including 1% carbon and 10% chromium, which can help to give strength and longevity, and multiple properties. These bars have a number of benefits, especially for high-temperature applications.

Construction Properties of Stainless Steel Bars

Stainless steel bars are used in the mechanical as reinforcement, and construction sectors with the wear-resistant and superior tensile and ductility. Stainless steel bars perform well, withstand corrosion resistance and improve structural strength performance.

Basic Composition in Carbon Steel Bar

The Standard composition of carbon steel bars is mainly iron (Fe) and controlled amounts of carbon (C), the remainder being made up of trace elements. Its carbon content usually varied from 0.05 percent to 1.5 percent and determined the steel’s hardness as well as tensile strength. Manganese (Mn) is present in all commercial steels as an added impurity. It can be reduced to about 0.3-1.5% while simultaneously maintaining the capability of hot-working and strength increasing. Small traces of silicon (Si), phosphorus (P) and sulfur (S) are also found. They are kept at low levels to ensure toughness and weldability with phosphorus and sulphur usually regarded as impurities. This basic iron-carbon alloy is the most commonly used form of steel.

Construction properties of Carbon Steel Bars

The carbon steel bars are great for construction due to its tensile strength and high corrosion resistance. Under load they deflect predictably and give warning before failure. They can be bent and shaped on-site without cracking due to their ductility. They have excellent weldability and good machinability, making these materials a multipurpose choice. The elasticity modulus provides the constant high stiffness and low deformation under load. Although they can corrode (and do need to be coated) their strength-to-cost ratio is amazing. These features rank carbon steel bars as the most durable and reliable reinforcement material available for concrete, frameworks and infrastructure, providing a long life expectancy without attracting the structures.

Cost Comparison of Stainless Steel Bar VS Carbon Steel Bar

The cost of stainless steel bars is much higher compared to carbon steel bars, usually amounting to three-five times by weight. This premium is largely influenced by the alloying elements, mainly chromium (minimum 10.5%) and in many cases nickel, which are expensive and insatiable in terms of price and development.

The greater cost of stainless steel for certain corrosion resistant, sanitary or high temperatures applications is justified. For overall good construction and manufacturing needing strength more than corrosion resistance, carbon steel is the best material choice.

Which Metal Should You Choose?

Choosing between Stainless Steel and Carbon Steel Bars comes down not to which one is “better” but rather, which one is better suited for your particular project’s needs and budget.

You want carbon steel if:

- Cost is your number one priority.

- Application demands very high strength and toughness.

- Corrosion is controllable through the use of protective coatings (such as painting or galvanizing) or the environment is not applicable.

Stainless Steel will be the perfect choice for you, if:

- Corrosion resistance is also a significant factor(e.g. Marine application, chemical processing or food/medical equipment).

- Looks good but no maintenance is required.

- The investment is higher initially but in the long run the durability and low maintenance of the project will justify that rise.

Conclusion

The decision whether to go with carbon steel or stainless steel bars is a trade-off between upfront cost and long term performance. Carbon Steel is the most cost-effective choice and provides long term value for less strong application. On the other hand, stainless steel offers a high resistance to corrosion and wear – offering better durability and justifying its higher initial cost in harsher environments which will save on long term maintenance costs. Ultimately, the choice is applications-specific-value-based and where budget,strength and aesthetics are key; carbon steel or when corrosion resistance, hygiene & lifecycle costs exceed all other; stainless steel. There is no material that is in all respects the “best” i.e. for each and every application, including cost.